Discharge Solutions for Grinders

Discharge Solution for Grinders - Horizontal Belt Conveyor

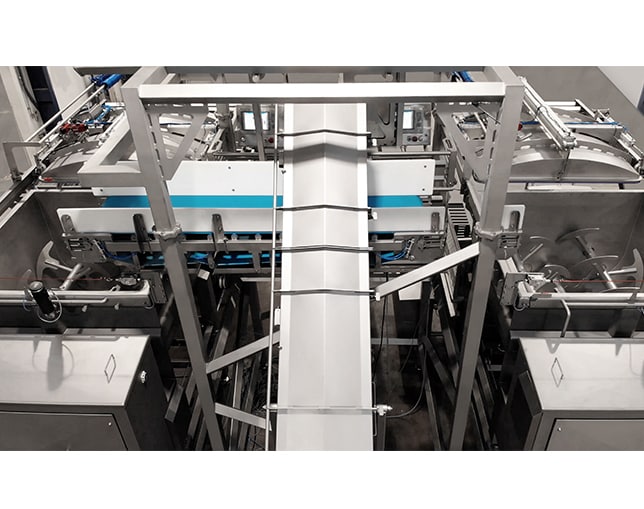

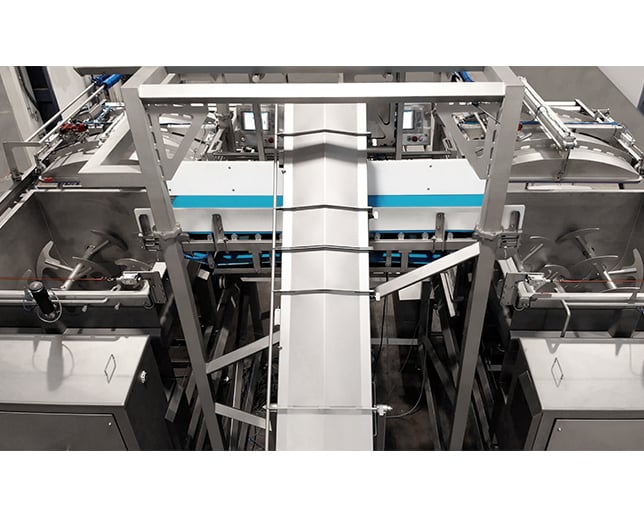

Another typical horizontal belt conveyor solution where 2 (two) grinders are discharging onto the scansteel foodtech® belt conveyor. This solution saves a lot of safety devices and, at the same time, secures easy access to the grinders for cleaning, mounting, and dismounting of the grinders.

Front view.

Top view.

Discharge Solution for Grinders / Feeding of Mixers - Screw Conveyor & Belt Conveyor Solutions

scansteel foodtech A/S supplies various solutions where screw- and belt conveyors are combined. A typical solution

might be discharging from one or two grinders into two or more mixers.

might be discharging from one or two grinders into two or more mixers.

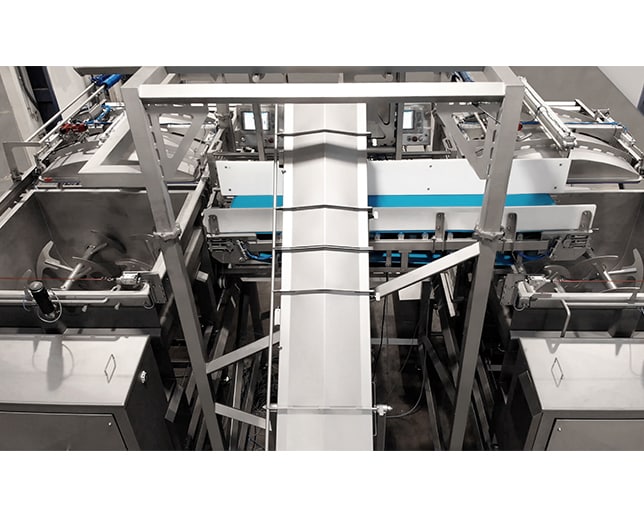

Close-up view showing scansteel foodtech® inclined screw conveyor feeding onto a scansteel foodtech® horizontal belt conveyor which has 3 (three) main positions.

This position shows the belt conveyor feeding a scansteel foodtech® mixer on left hand side.

This position shows the belt conveyor in neutral position in order for both mixer lids to be capable of closing.

This position shows the belt conveyor feeding a scansteel foodtech® mixer on right hand side.