PRODUCT TRANSFER EQUIPMENT

station, seen from infeed

side.

station, seen from

discharge side. Weighing

belt positioned on load

cells. Drip tray underneath

to prevent dripping on floor.

Table split into two units:

one for unpacking of

frozen blocks and one for

weighing of batches.

scanLift single and double

column

scanGiraff standard, with

buffer silo and for

heavy duty applications

with hydraulic knockdown

system for cleaning,

inspection and maintance

Product Transfer Equipment

scansteel foodtech A/S manufactures a wide range of:

• Screw conveyors – inclined and horizontal.

• Giraff screw conveyors (horizontal/vertical as one unit)

• Vertical screw conveyors – for mounting directly on outlet of grinders.

• Lifting devices – single/double column.

• Tilt dumpers/swing loaders, hydraulic – single and double column.

• Silo buffer systems from 500 L – 12,000 L.

• Weighing and batching systems – manual or automatic dosing of pre-programmed batch sizes.

Batching & Weighing

Inclined Screw Conveyor

Inclined Screw Conveyor

scansteel foodtech® standard scanGiraff

scansteel foodtech® scanGiraff with Buffer Silo

scansteel foodtech® scanGiraff for Heavy Duty Applications

scansteel foodtech® scanLift Single Column

scansteel foodtech® scanLift Double Column

Special application/lifting devices

Silo System

Each silo is typically from 2000-10.000 litres. Each silo is capable of storing pre-ground frozen material as well as fresh raw meat material.

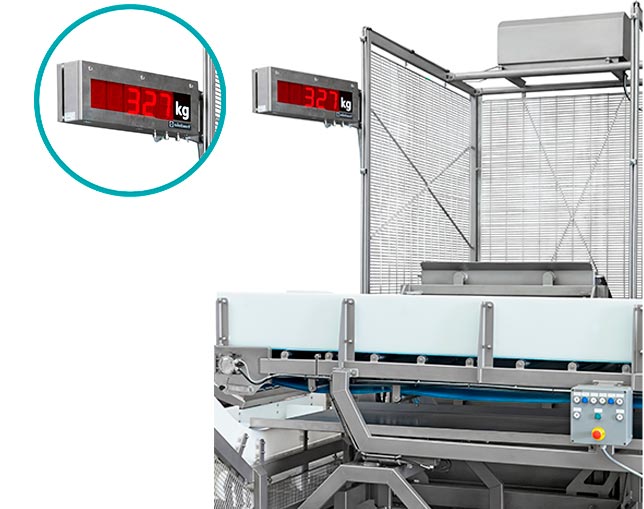

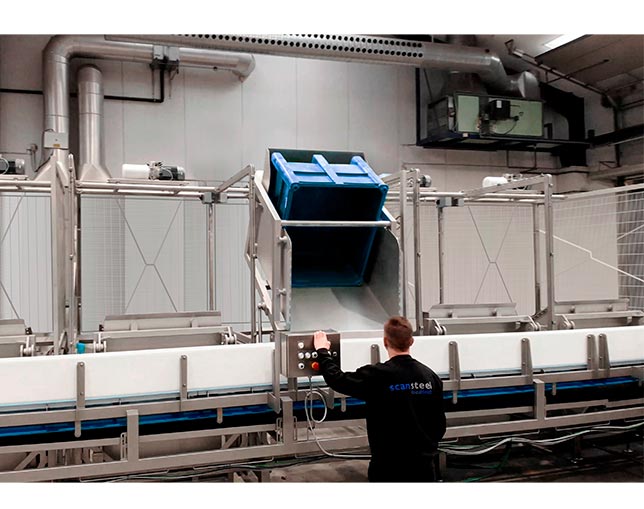

Swing loader with weighing belt and weight indicator

Is a line consisting of 3-10 swing loaders which demands 1 (one) person only.

Infeed Systems

Unpacking/Unwrapping table with optional weighing/load cells and unpacking station with 2 (two) lifting tables for ergonomics

Belt Conveyors