Storage & Batching Systems

station, seen from infeed

side.

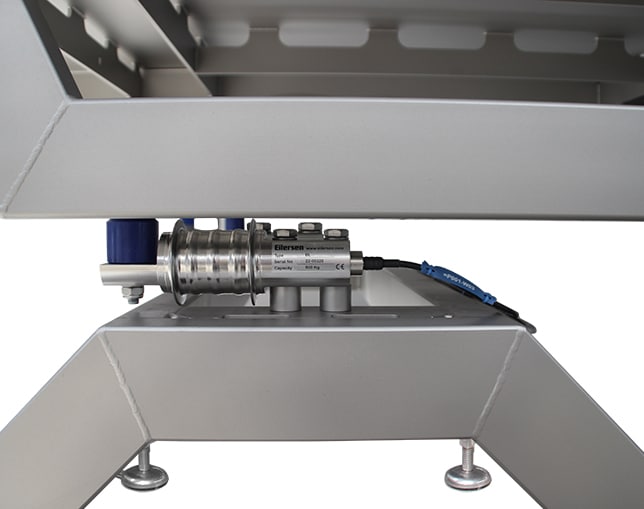

station, seen from

discharge side. Weighing

belt positioned on load

cells. Drip tray underneath

to prevent dripping on floor.

station, seen from

discharge side. Weighing

belt positioned on load

cells. Drip tray underneath

to prevent dripping on floor.

Storage & Batching Systems

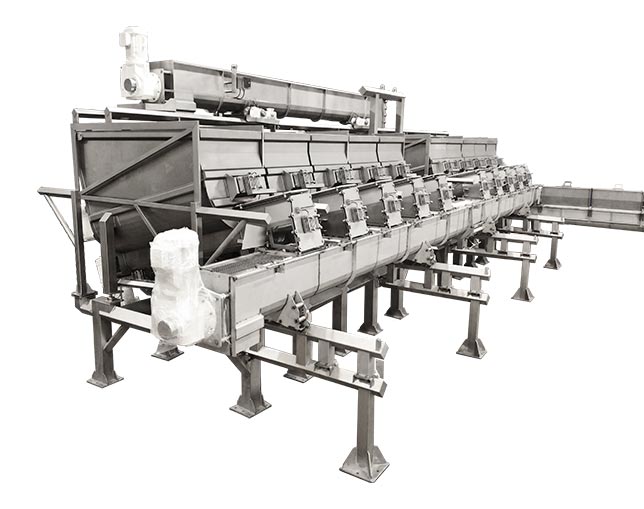

Silo Systems

Each silo typically from 2000 – 10,000 liters. Each silo is capable of storing pre-ground, frozen meat raw material as well as fresh meat raw material. Each silo is typically equipped with a stirring device/wing to prevent pre-ground meat raw material from freezing together, and is typically equipped with weighing-/load cells to accurately control the batch weight just as the weighing-/load cells are used to accurately weigh out the exact amount(s) according to the recipes. The scansteel foodtech® silos are typically equipped with a discharge screw which handles both pre-ground frozen- and fresh meat raw materials.

scansteel foodtech® 10 unit silo system with 3000 liter silos, shown below. Showing both horizontal infeed screw for feeding the silos as well as discharge screw showing how the batching and discharge of the silo system. Typically, each scansteel foodtech® silo is equipped with load-/weighing cells and as such the silos can discharge simultaneously in order to create pet food recipes fastest possible, and without delay. It is also shown that the large discharge- and batching screw can easily be pulled out for inspection and maintenance.

View of the silo discharge screw of the silos showcasing the easy access for cleaning and inspection without hidden surfaces.

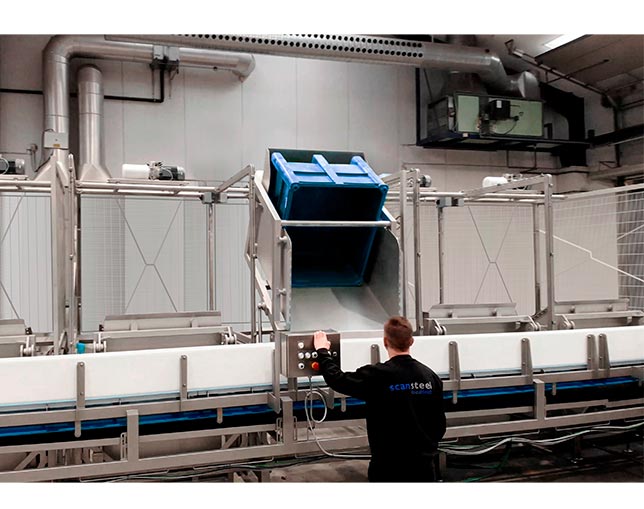

Swing Loader with Weighing Belt

6 (six) unit weighing station, seen from the infeed side. Typically, Dolav bins are fed into the swing loaders by a fork lift truck. All is controllable from the operator panel.

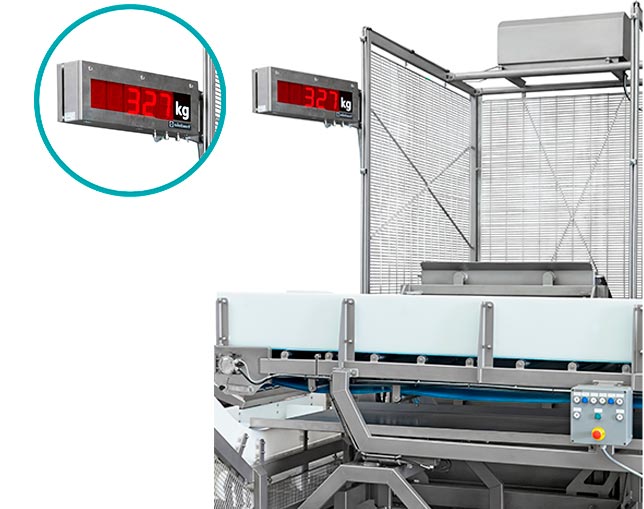

6 (six) unit weighing station, seen from the batching/weighing side. The operator looks at the control panel to the right to check how many kilos he requires of a certain meat raw material. Next, the operator looks at the operator panels in front of each swing loader to see where he has to unload/weigh out the volume of meat required. The weighing belt is equipped with 4 (four) loads cells in order to monitor weights continuously.

Swing Loader with Weight Indicator:

Overview of the entire weighing and batching station, seen from the batching/weighing side.

Control panel for operator and details showing drip trays and

weighing/load cells.

Batching & Weighing

One option in the scansteel foodtech® “batching family of solutions” is a station of typically 2 – 8 swing loaders (tippers) which can hold different meat raw material.

With the scansteel foodtech® line control, it is possible to guide the operator into the exact amount of each meat raw material to be unloaded onto the weighing/batching belt conveyor.

Unpacking Of Frozen Blocks - Tables

scansteel foodtech® unwrapping table.

scansteel foodtech® lifting table.